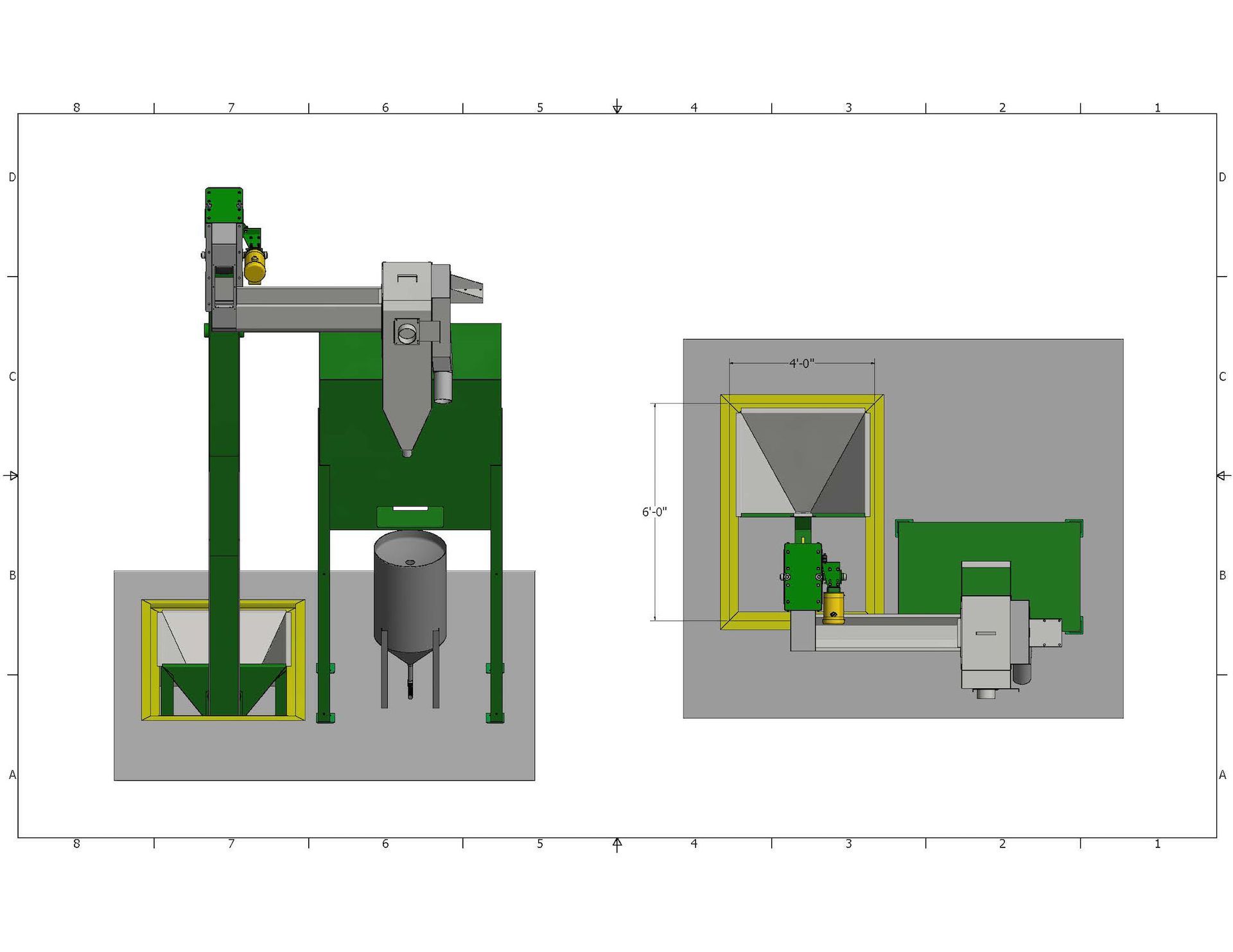

Sandblast Reclaim Systems

Reclaim and reuse your sandblasting materials

Secure & Save Your Sandblasting Materials

With a professionally designed and installed blast recovery system, you’ll hardly lose an ounce of your abrasive blast. Our recovery systems meticulously separate the abrasive blast from waste dust, meaning you spend less money replacing reusable blast.

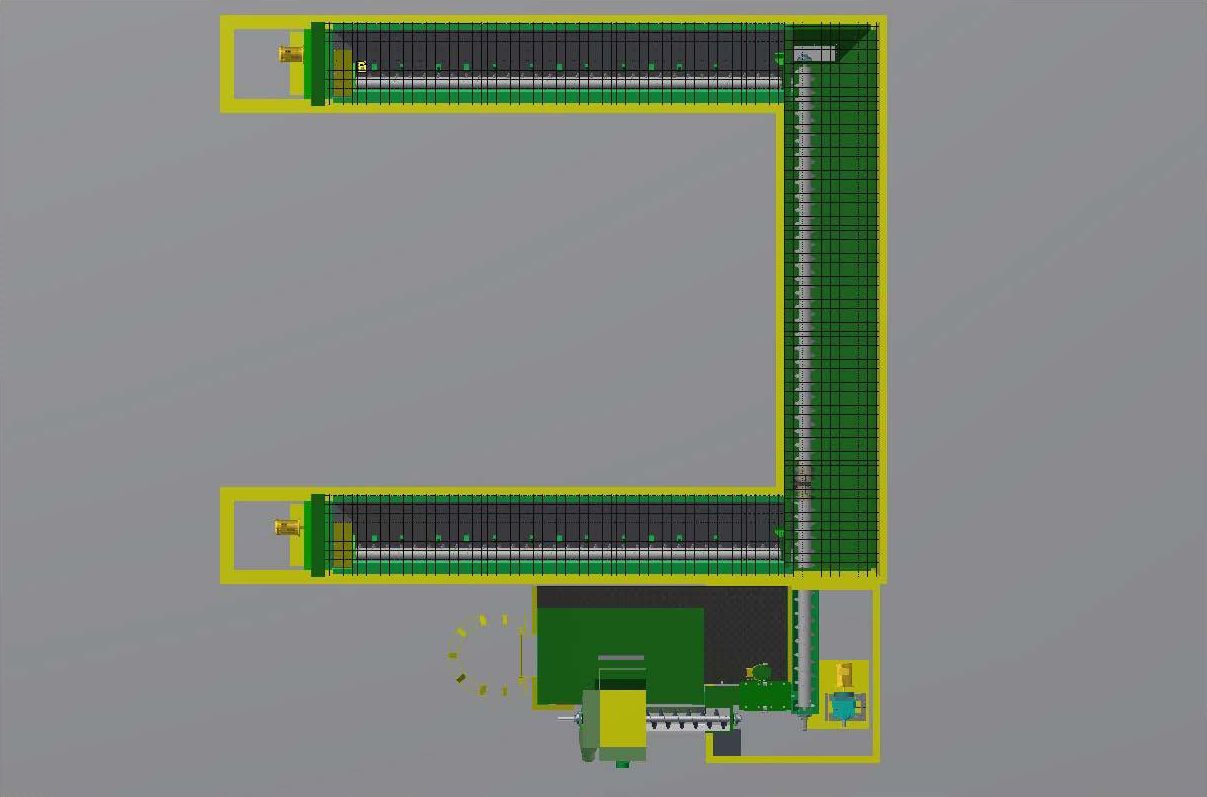

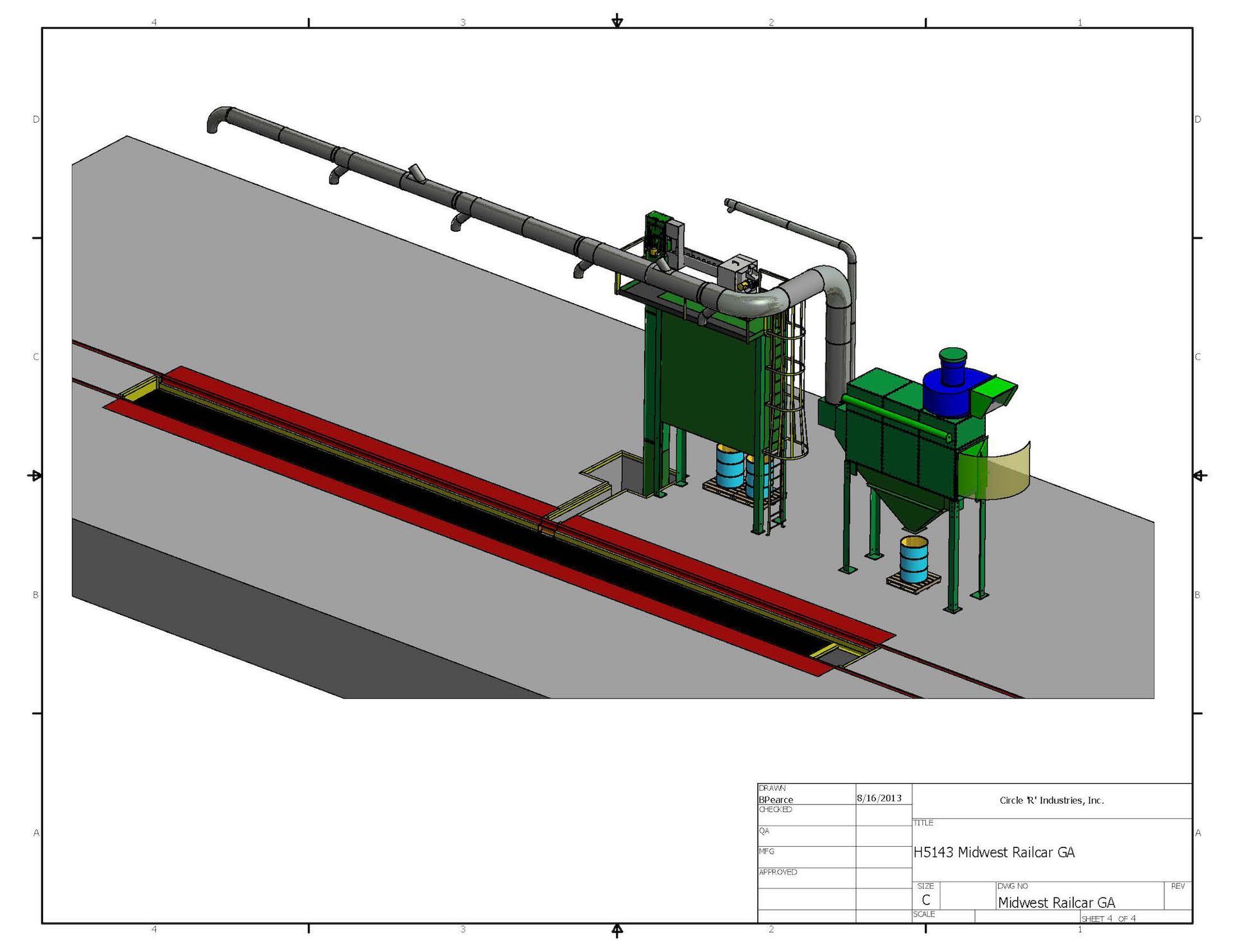

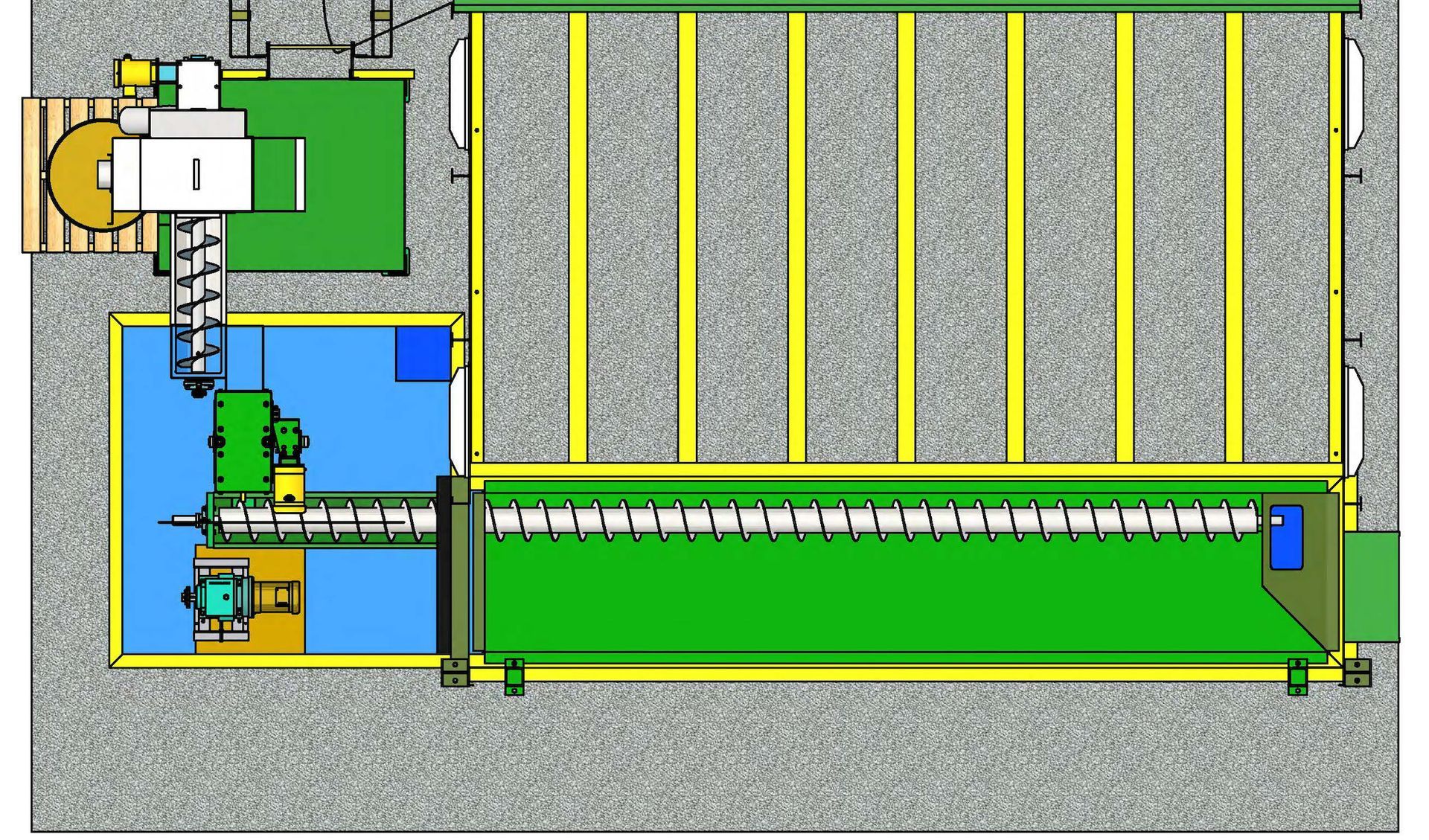

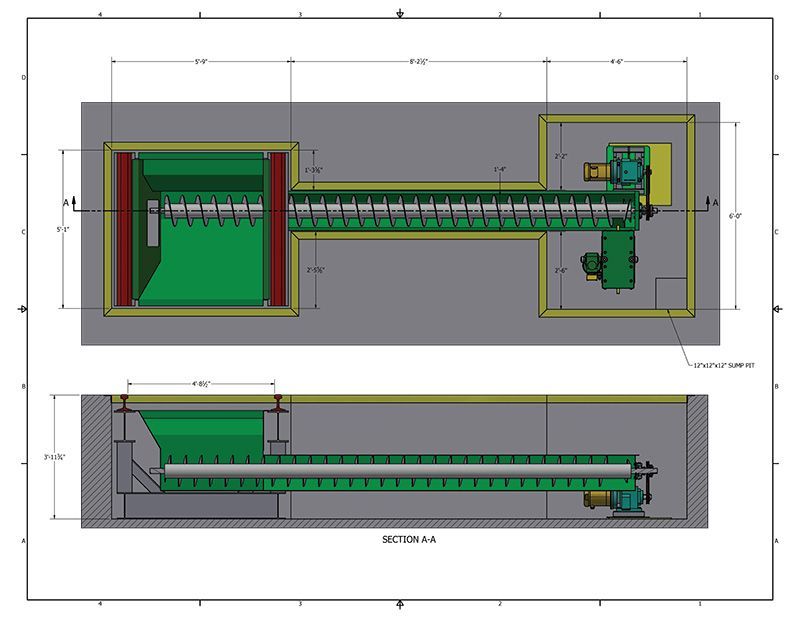

Choose The Right Reclaim For The Job

Find the perfect blast recovery system for your business. A simple corner sweep that feeds an elevator, an auger system, a full floor recovery system – whatever you need, we can help.

Ensure Your Crew Breathes Easily

With a professionally designed and installed blast recovery system, you’ll hardly lose an ounce of your abrasive blast. Our recovery systems meticulously separate the abrasive blast from waste dust, meaning you spend less money replacing reusable blast.

Here’s How We’ll Work Together

1. Start the conversation

Talk to the team about your reclaim system needs and goals.

2. Site visit and analysis

We’ll visit your site to explore existing infrastructure and opportunities.

3. Design and planning

With data from our visit, we’ll create an informed, thoughtful blast recovery design.

4. Construction and installation

Your reclaim system will be manufactured and installed with skill and know-how.