Build an Unstoppable Blast Room

Blast room design and construction that solves your workflow problems

Blast Room Systems

There’s much more to a blast room than quality parts and construction. We’ll help you analyze and plan every part of your blast system until the workflow is flawless.

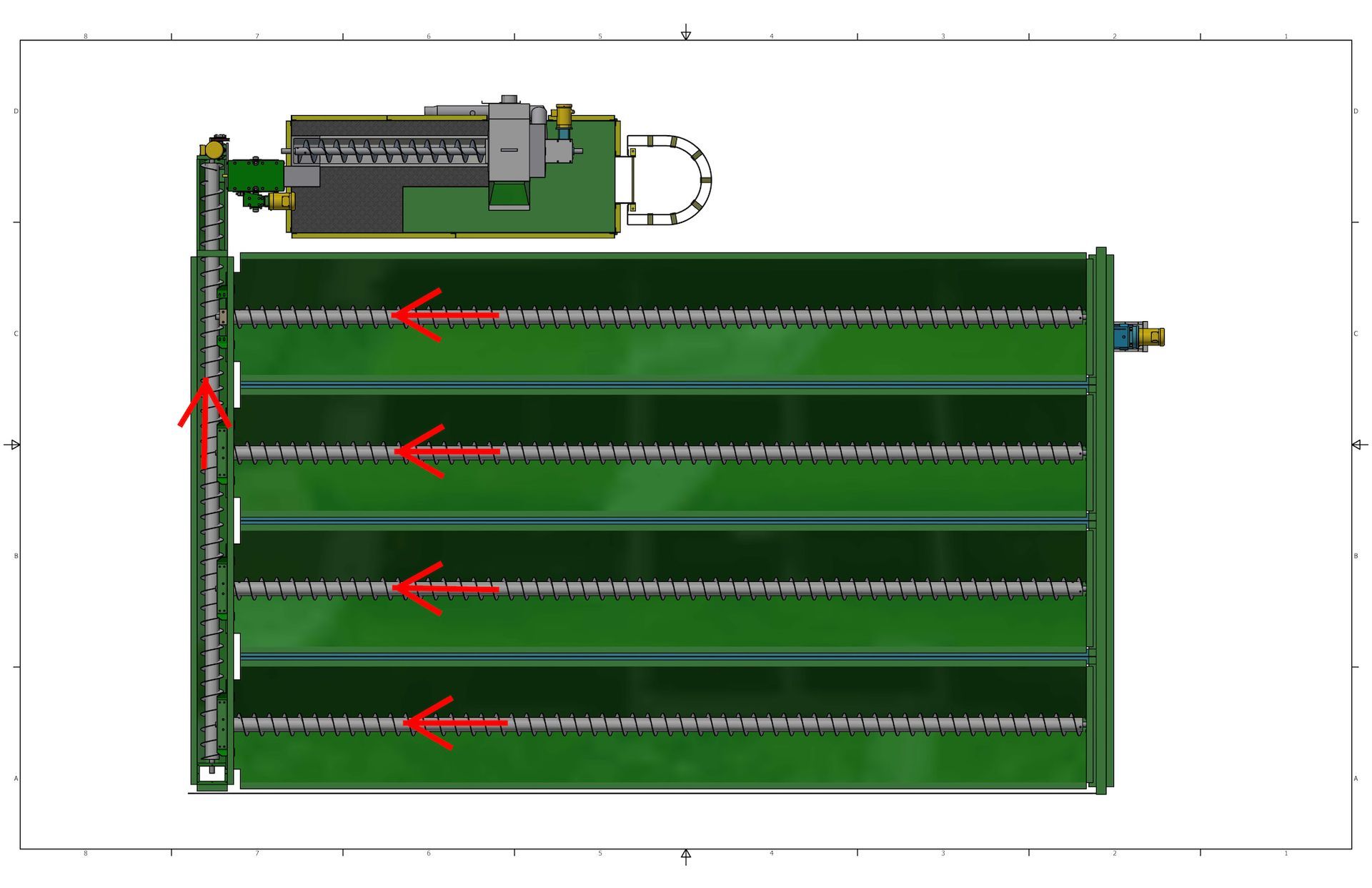

Reclaim Systems

Reimagine an older blast system with help from industry-leading expertise. Then rebuild it with construction and parts that are unmatched for durability and ingenuity.

Hoffman Blast System Parts

We manufacture the parts that make your blast room sing. From standard pieces to custom tools, there’s pride and craftsmanship in every part we make.

Custom-Engineered Buildings

Unique sandblasting requirements don’t scare us. With decades of industry experience, we can design a custom blast room or building that’s ideal for your goals.

Build an unstoppable blast room

Blast room design and construction that solves your workflow problems

Avoid costly production downtime

Tagline here

Clean products faster so you can sell them sooner

You need to finish your parts, railcars, barges, or trailers at a pace that meets demand and keep production costs buoyant. To do that, you’ll need a rock-solid blast room.

The right blast room design anticipates your workflow issues and solves problems before they start. And with sound construction from the industry’s most trusted name, you know your blast room will work as hard as you do.

With over 50 years in the field, we know what works – and what doesn’t – in blast room design and construction.

Complete Blast Rooms

Start with a blank room and watch a phenomenal sandblasting system take shape. With our experts by your side, you’ll build a blast room that anticipates workflow problems and meets your output requirements.

Reclaim Systems

The abrasive materials you use to blast your metal products can be reused, saving money and creating a circular system that avoids waste.

Hoffman Blast System Parts

If you’re already familiar with the long-lasting quality of Hoffman Blast System parts, you won’t settle for less than the best. Whether you need a standard piece or a custom part, we can help.

Custom-Engineered Buildings

House your operations in a strongly-built metal building, perfect for anything from manufacturing to production line. New metal building construction is cost-effective in the short and long term.

Speed Up Production with a Hardworking Blast Room

Whether you want to design a new sandblasting room from scratch or you’re reclaiming an aging system, we’ll help you create an innovative, ruggedly-built blast room system.

What do your blast rooms specialize in?

We build blast rooms for industrial-scale abrasive cleaning of tractors, parts, barges, railcars, and trailers.

How long does blast room construction take?

The average time to design, manufacture, and install a blast room is 6 months. For a smaller blast room, we could work in a 3-month timeframe.

Can you retrofit an older blast room?

Yes. With over 50 years in the industry, we’ve seen countless blast room designs come and go. We know what works, what doesn’t, and how to address old blast room problems so they can keep pace with modern manufacturing.

Do you create vacuum systems?

Vacuum systems are not in our range of specialties. We build robust blast rooms that require a big booth for heavy blasting.

Frequently Asked Questions

What do your blast rooms specialize in?

We build blast rooms for industrial-scale abrasive cleaning of tractors, parts, barges, railcars, and trailers.

How long does blast room construction take?

The average time to design, manufacture, and install a blast room is 6 months. For a smaller blast room, we could work in a 3-month timeframe.

Can you retrofit an older blast room?

Yes. With over 50 years in the industry, we’ve seen countless blast room designs come and go. We know what works, what doesn’t, and how to address old blast room problems so they can keep pace with modern manufacturing.

Do you create vacuum systems?

Vacuum systems are not in our range of specialties. We build robust blast rooms that require a big booth for heavy blasting.

Frequently Asked Questions

Questions?

We're here to help.

blast room contact form

We will get back to you as soon as possible.

Please try again later.