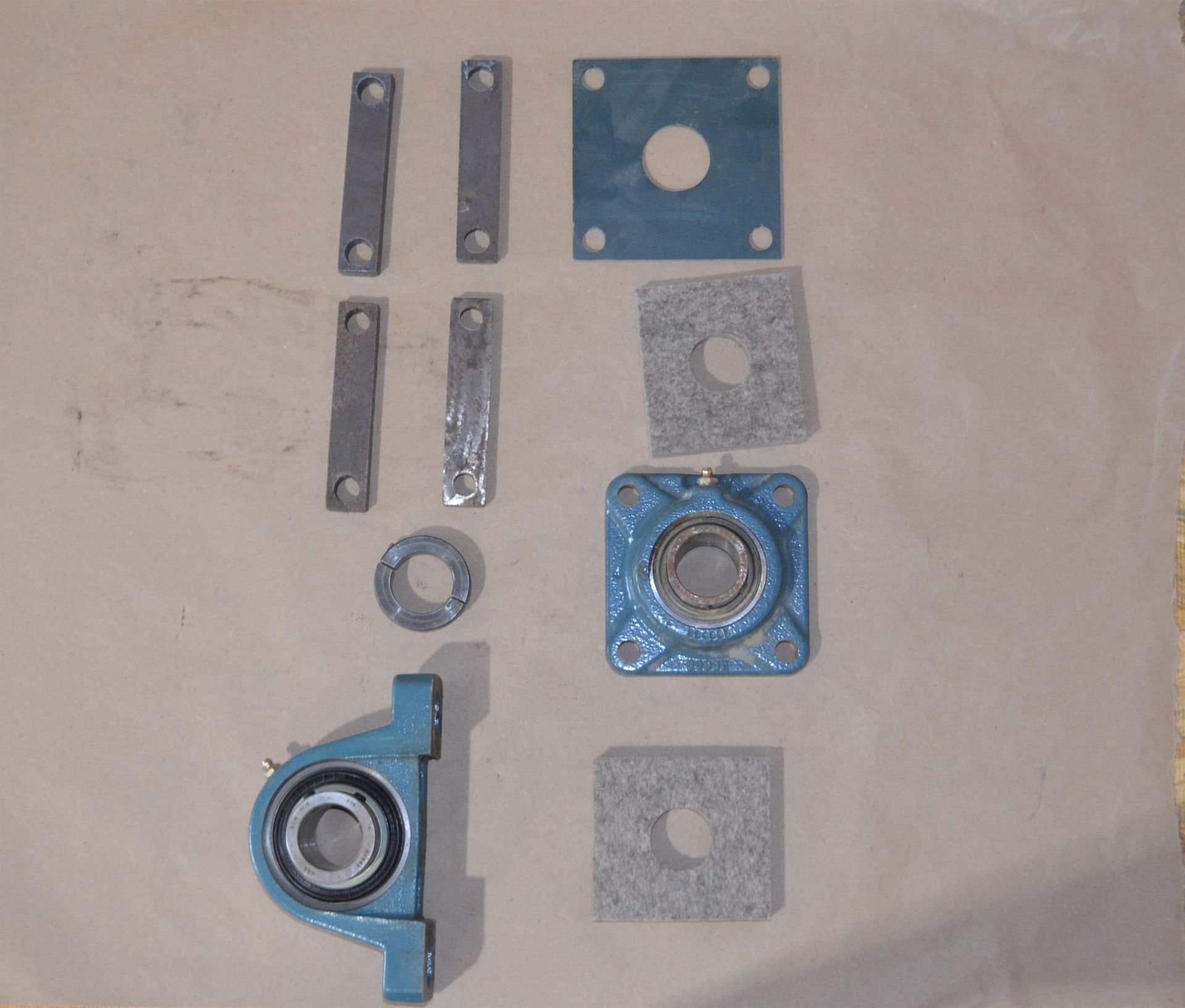

High Quality Sandblast Parts

Custom & standard sandblasting parts

Refresh your blast room for less

Replacing worn blast room pieces with high-quality parts is the most cost-effective way to extend the life of your abrasive cleaning equipment.

Buy the best in hanger bearing design

Our patented hanger bearing beats the traditional design by directing the water stream around an internal obstacle, increasing the force of the flow.

Industrial and commercial contracting

Whether it’s a single-day installation or a multimillion-dollar contract, we’ll make your metal commercial building project a success with unmatched know-how and crystal-clear communication.

Here’s How We’ll Work Together

1. Start the conversation

Talk to the team about the sandblasting parts you need.

2. We’ll check the shelves

We’ll check to see if we can find the right Hoffman Blast II part in stock.

3. Or design a custom piece

If you need custom sandblast parts, we’ll craft one with skill and care.